South Basic Chemicals Joint Stock Company solves the problem of “TECHNOLOGY INVESTMENT”

South Basic Chemicals Joint Stock Company is one of the companies with a long history in the production and trading of basic chemicals. Officially operating since 1976, up to now the Company has had a certain market share and position in the field of basic chemical production. Over 44 years, along with the continuous changes and upward movements of the country’s economy, South Basic Chemicals Joint Stock Company overcame many difficulties, promoted the tradition of solidarity, and successfully completed its tasks. to develop the company more and more, contributing to the stability and socio-economic development of the country. In which the work of “investment in technology” is an issue that has been well done by generations of leaders and staff and has achieved certain successes in recent years.

The years after the country was reunified (period 1976 – 1985): The socio-economic situation of the whole country was still difficult and complicated, with inadequate and poor facilities. The production-business environment is bound by subsidized production relations for a very long time, thereby failing to promote the initiative and creativity in production and business, and the role of scientific and technological progress. technique has not been given due consideration. Production forces are constrained, leading to poor productivity and product quality, and low living standards for workers.

Facing these difficulties and challenges, welcome the wind of renewal from the 6th National Congress of the Party, grasp the Resolution of the 7th Central Conference on the issue of industrialization and modernization of the country, with the foundation of love. In the spirit of collective ownership, all employees of the Company have firmly accepted the step-by-step transformation from a heavily subsidized economy to a socialist-oriented market economy under the leadership. of the Party. A series of activities on investment in innovation of technology, production lines, improvement of machinery and equipment, rationalization of production processes in order to increase output, quality, reduce product costs, and reduce pollution. Environmental pollution has been drastically deployed by the Company to meet the requirements of the market mechanism’s competition rules.

In many of the above problems, the solution of the problem of ” technology investment” is considered by the company as the core issue that determines the success or failure of the Company, so a series of requirements have been set on the selection of technology to invest in new investment projects that must meet the following requirements. request:

- New investment technology must be modern, have a high degree of automation, and use new materials of superiority;

- Product quality is good, stable, has a competitive advantage in quality;

- Low operating costs;

- Saving energy and raw materials;

- The production line operates stably and reaches the designed capacity;

- Long equipment life, safe operation;

- Ensure emission standards for environmental protection;

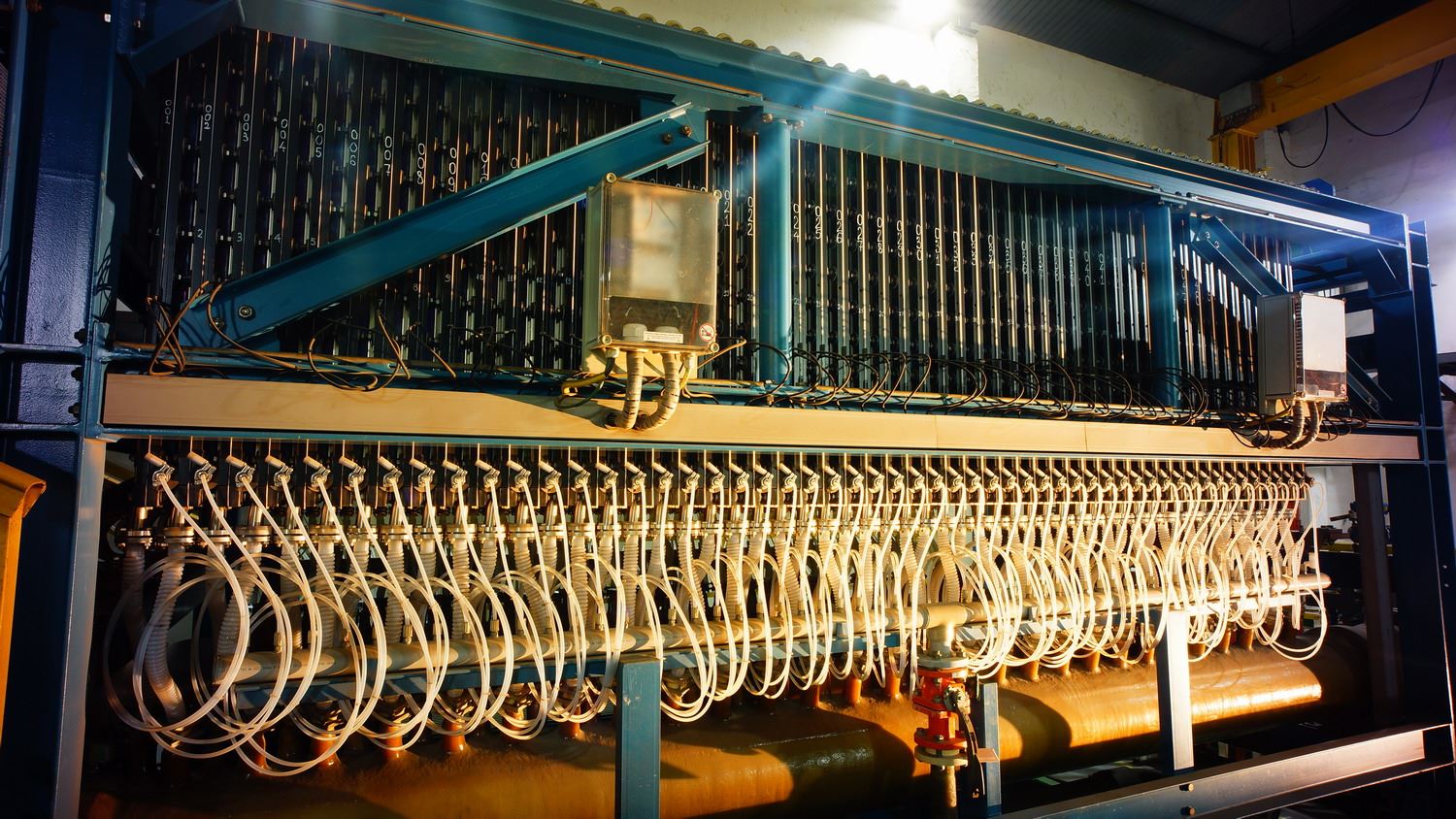

Currently, the company’s caustic soda-chlorine production line uses ion-exchange membrane electrolysis technology, which is the most advanced technology currently provided by thyssenkrupp Uhde Chlorine Engineers (Italy) Srl (tkUCE) with the generation of batteries. BM2.7 gen 6 fertilizer is the latest and most modern generation, ensuring optimal promotion of capacity, increasing product quality and stability, completely meeting Food Chemical Codex and chemical standards. food additives, production costs and power consumption are reduced, ensuring the highest level of environmental and environmental safety, modernity and full automation. The investment stages in the past years are as follows:

- Starting in 1993, the Company has invested in converting caustic soda production technology to ion-exchange membrane technology (which is the most modern technology in the world at this time) with a starting capacity of 500 tons. caustic soda 100% NaOH/year, in the form of new investment and removing the entire old electrolysis line. This is a breakthrough investment project, thereby creating motivation for the Company to continue to invest and renovate and increase the capacity of all other product production lines throughout the Company. In the following years, the Company continued to invest in improving the capacity of caustic soda to 10,000 tons/year, then increase the capacity to 15,000 tons/year – generation of DD350 and 20,000 tons/year electrolytic cell (of which 5,000 tons/year). year is the generation of electrolytic cell BM2.7 Gen 3; and increase the capacity of hydrochloric acid 32% from 16,000 tons/year to 56,000 tons/year; accompanied by investment in technological equipment and production lines to solve the problem. solve the problem of caustic soda – chlorine balance, such as increasing the capacity of products: liquid chlorine from 1,750 tons/year to 8,400 tons/year, silicate to 18,000 tons/year…. In 2010, the Company increased the capacity of caustic soda to 30,000 tons/year – continued to invest in the generation of BM2.7 gen 3 electrolytic cell, synchronously raising the capacity of hydrochloric acid to 75,000 tons/year, increasing the silicate capacity to 30,000 tons. /five. In 2019, the company increased the capacity of the caustic soda line to 40,000 tons/year and now the company is investing to increase the capacity of caustic soda to 50,000 tons/year with the same generation of BM2.7 gen 6 electrolytic cell which is the latest generation, most modern today.

- Besides, in 2005, implementing the policy of moving production factories out of residential areas of the People’s Committee of Ho Chi Minh City, in the process of moving Tan Binh Chemical Factory (HCMC) to Bien Industrial Park. Hoa 1, Dong Nai province. The company has strongly expanded its sulfuric acid production capacity to 60,000 tons/year with advanced technology of double contact (3×2), the ability to recover excess heat using the heat of the line to produce highly efficient steam. , using new generation equipment, new generation materials that are resistant to corrosion in the specific environment of high concentration and high temperature sulfuric acid, the line is equipped with DCS automatic control system. As a result, this line produces very good quality products compared to current sulfuric acid factories in Vietnam, the line operates stably, promoting 100% of the designed capacity; Especially, the operation cycle is maintained up to 3 years, reducing the downtime of the machine for repair and maintenance of the line up to 3 times compared to the previous line of the Company.

- In addition to investing in innovation of caustic soda – chlorine production technology, the Company also researches investment technology to manufacture high quality products such as: PAC; technical and food grade phosphoric acid; pure sulfuric acid; other high-quality products used in the food industry, food additives, cosmetics, etc.

Orienting production technology in the period of 2020-2025, the company intends to implement a number of tasks:

- “Researching technology and deploying production of chlorine-based products” to create new products, further effectively solve the problem of caustic soda-chlorine balance, increase production and business efficiency. Specific products such as Chloramine B; Trichloroisocyanuric acid (TCCA).

- “Research on technology to use heat source in hydrochloric acid synthesis reaction, to produce steam” solves the problem of efficient use of heat, saving energy and increasing production and business efficiency.

Assessing the development potential and prospects of the unit by solving the problem of “technology investment”:

The domestic market demand for caustic soda – chlorine products is very large. The development of related industries creates conditions for the Company to increase the capacity of production lines and expand product categories to meet market demand.

The Company’s products are manufactured on modern technology lines, with high and stable product quality, meeting the strict requirements of the food, chemical, pharmaceutical, and electronic industries, so they are always popular with customers. trusted and appreciated goods. Especially for customers with high requirements for quality.

The production lines of caustic soda – chlorine, acid of the company have the main technology and equipment supplied from famous chemical manufacturers in European/G7 countries with modern advanced production technology, so quality Quality of products such as caustic soda, hydrochloric acid, sulfuric acid and many other products of the company meet international standards and good quality (exceeding TCVN).

Thanks to boldly focusing on investing in technological innovation and increasing the capacity of product production lines, the products manufactured by the Company have stable product quality, meeting the rapidly increasing demand of the market. market in terms of quantity, quality and price, accepted by customers and achieved high efficiency, next year’s profit is higher than the previous year, contributing to the target of total output value, revenue, profit. profits and the obligation to pay the state budget. Notably, the living standards, income, working conditions and workers’ consciousness are constantly improving according to the general level of the region.

In the current economic situation, there are many changes and complicated developments, but thanks to the foundation of the production technology chain system, it is always focused on investing in innovation, applying modern technologies to products. As a result, the Company’s business activities are always developing stably, so the income of employees in the Company is always guaranteed and is considered good compared to domestic enterprises producing and trading in the same line of products. This shows the Company’s change and adaptation to the rapid changes of the country’s economy. With the efforts of the whole Company and the support of the Vietnam Chemical Group, in the past 5 years, the income of employees has reached a high level.

After transforming its operating model to a joint stock company, the Company has focused on implementing many strategic solutions, notably mobilizing resources to invest in upgrading and expanding production lines. using modern technology, in order to improve productivity and quality, reduce product costs, meet market demands, improve production and business efficiency, and orient the company’s products towards customers. food, pharmaceutical and food additive industries, ready for future expansion and development plans.

Southern Basic Chemicals Joint Stock Company